KH Inspection and

Maintenance Service

AVAILABLE

NATIONWIDE.

PART OF OUR HOLISTIC RANGE OF SOLUTIONS.

Following the harmonisation of the Water Resources Act (WHG) under EU law, the majority of dome shafts and remote fill sumps at petrol stations no longer comply with the applicable regulations and requirements. In light of the precarious market situation, this presents yet more financial uncertainty. However, what may at first appear to require a full replacement often only requires renovation.

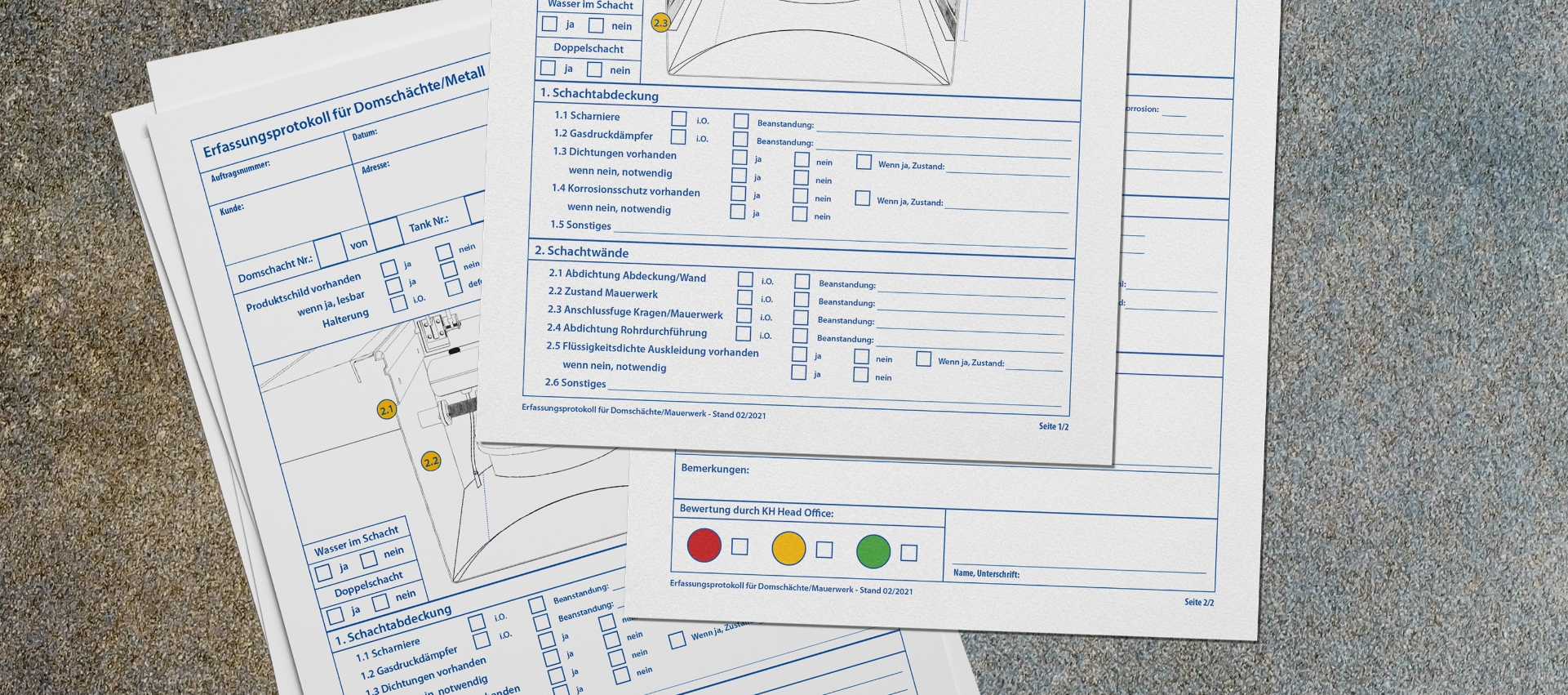

In accordance with Section 24(3) of the the Ordinance on Facilities for Handling Substances that are Hazardous to Water (AwSV), a condition assessment needs to be carried out before repairs are performed on a system or parts of a system along with the creation of a repairs plan.

Our inspection service makes us the ideal partner for all your assessment needs. We undertake a condition assessment for all of your storage, filling and handling facilities and facilities used to handle water-polluting substances in compliance with all relevant standards and regulations. After this, we create a holistic tank renovation concept designed to save you time and money. The service is rounded off with a detailed, official report.

KH INSPECTION SERVICE

BENEFITS AT A GLANCE.

AVAILABLE

NATIONWIDE

ON-SITE CONDITION

ASSESSMENT

DETAILED

REPORT

QUALIFIED

RENOVATION CONCEPT

RELIABLE

CALCULATIONS

CERTIFIED

MEASURING TECHNOLOGY

THE KH

INSPECTION SERVICE

SAFEGUARDS YOU

AGAINST EXPENSIVE

CONSEQUENTIAL DAMAGES.

Along with innovative testing and analysis methods, our customers benefit from the extensive experience of our inspection specialists.

Regular servicing can help petrol station operators avoid major damage and the corresponding restricted operations.

By analysing the target and current wall thickness using ultrasound technology, our KH inspection specialists can precisely assess the condition of the tank wall and discuss necessary action with you in good time. Our certified cold casting process (TPS) enables us to safely and permanently seal leaks during ongoing station operations.

„Full replacement isn’t always

the only solution.

We’re proud

to do our part to protect

you and the environment.“

INSPECTION REPORT

FOR THE AUTHORITIES/INSPECTION BODIES

TRANSPARENT AND

RELIABLE.

Our inspection reports satisfy the requirements of the AwSV and the WHG. They are adapted to the specific conditions and materials at your site to account for the different recommendations for action arising from differing use requirements.

We then create a personal renovation concept with reliable calculations based on the report. Once the renovation is complete, we provide the customer with detailed, clear documentation containing operating instructions and describing the action to be taken in the event of damage. This ensures all official requirements are met and the process is transparent for the customer.

LEARN MORE ABOUT

OUR SOLUTIONS

AND SERVICES.

Cold casting compound patented by KH

with DIBt approval.

in accordance with the WHG

Corrosion protection/industrial coatings in accordance with

ISO12944 and NORSOK M501