Tank Protection Shield®

(TPS)

DAUERHAFTER

KORROSIONSSCHUTZ

DURCH ABDICHTUNG

MIT DIBT-ZULASSUNG

Für die zuverlässige Instandsetzung bei laufendem Betrieb

Tank Protection Shield® (TPS) steht nicht nur für ein fortschrittliches Abdichtungsmaterial, sondern für eine umfassende Lösung. Das Ziel ist es, Ihre Anlagen bzw. Domschächte effizient und kosteneffektiv instand zu setzen und anschließend nachhaltig zu schützen. Und das alles, ohne Ihren laufenden Betrieb zu stören. Ihr Geschäft kann ohne Umsatzeinbußen weitergeführt werden. Wie eine Schildkröte, die ihre Panzerung selbst heilen kann, reparieren wir mit Tank Protection Shield® (TPS) Ihre Tankanlagen wie neu!

Nutzen Sie die Effizienz von Tank Protection Shield® für Ihren Betrieb

Mit der DIBt-Zulassung garantiert Ihnen TPS höchste Standards im Hinblick auf Qualität und Sicherheit. Unser Service umfasst den gesamten Prozess – von der Analyse bis zur vollständigen Abdichtung Ihrer Tanks und Silos. Vertrauen Sie auf KH Tankschutz, Ihren verlässlichen Partner im Bereich Tankschutz. Die Umsetzung Ihrer Sanierungsprojekte erfolgt durch die Tank Protection Shield Service GmbH & CO. KG; das sind unsere ausführenden Spezialisten innerhalb der Heine Unternehmensgruppe, die unsere hohen Standards an Qualität und Effizienz teilen.

TANK PROTECTION SHIELD®

VORTEILE

100 % DAUERHAFTER

CARBONSCHUTZ

Freuen Sie sich über dauerhaften Schutz und bewahren Sie Ihre Anlagen zuverlässig vor Korrosion.

JAHRE

GEWÄHRLEISTUNG*

Sichern Sie sich 5 Jahre Gewährleistung durch den Abschluss eines Wartungsvertrages.

UMSETZUNG IM LAUFENDEN BETRIEB

Die Anwendung erfolgt während Ihres laufenden Betriebs, ohne Störungen Ihrer Geschäftstätigkeiten.

HOHE

KOSTENERSPARNIS

Profitieren Sie von hohen Einsparungen im Vergleich zu traditionellen Sanierungsmethoden.

* Bei Abschluss eines Wartungsvertrages.

THE SAFE SEVEN

Das sichere TPS

Verfahren

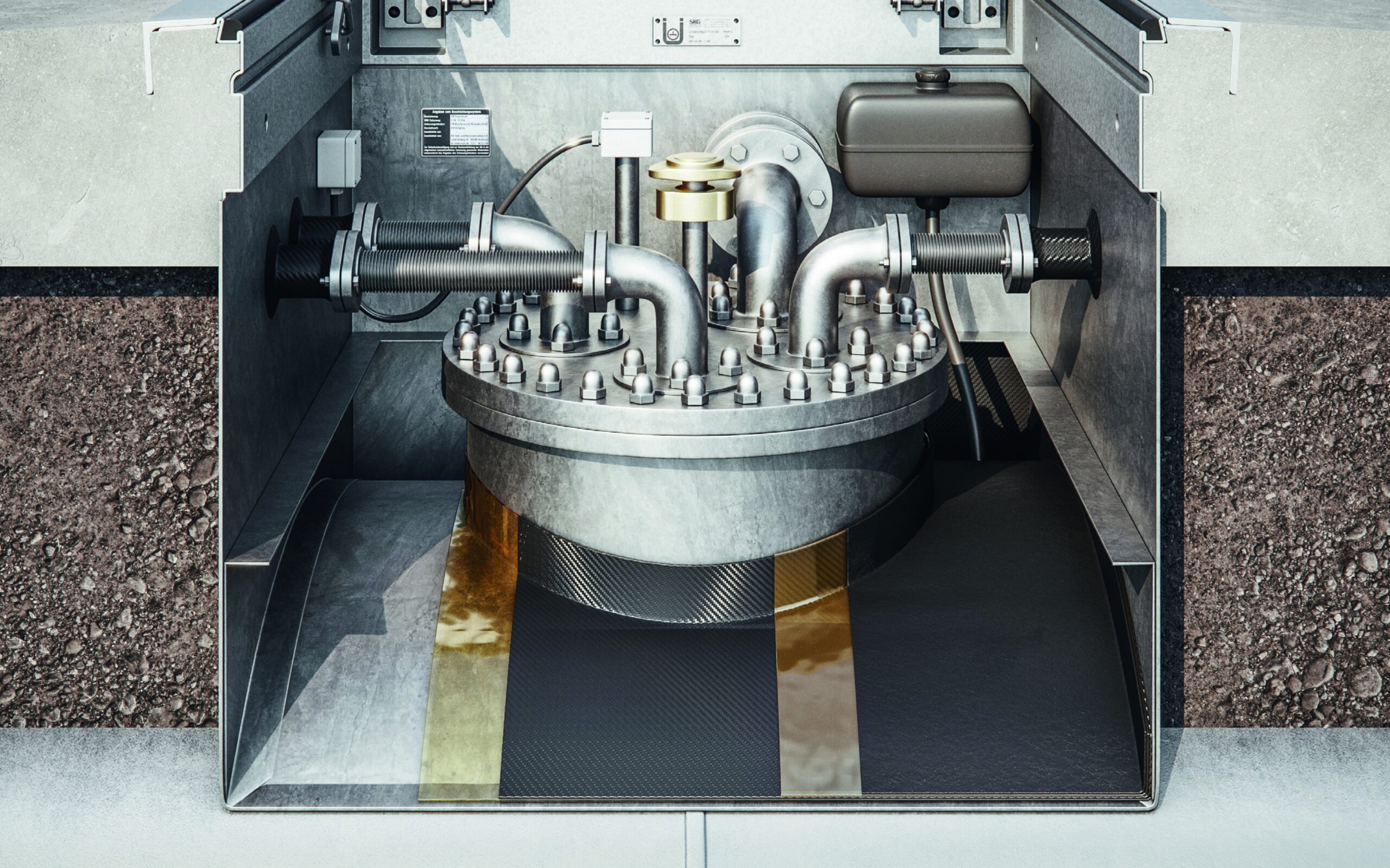

Ihr stärkstes Team gegen Korrosion: Liquid Power Plate und Tank Protection Shield®

Setzen Sie auf die Kraft der einzigartigen Hybrid-Lösung. Für Ihre Leckage-Reparatur und dauerhaften Schutz haben wir Liquid Power Plate und Tank Protection Shield® entwickelt. Beide zusammen ergeben eine optimale Synergie und Vorteile für Ihr Unternehmen wie nie zuvor.

Was Liquid Power Plate für Sie leistet

LPP – Liquid Power Plate wird oft das „Kraftpaket zur Riss- und Leckageabdichtung“ genannt. Diese fortschrittliche Metall-Polymer-Kombination ist die Antwort auf Ihre Herausforderungen bei der Abdichtung. Sie kombiniert die Beständigkeit von Metall mit der Flexibilität von Polymeren zu einer einzigartigen Lösung. Als vollwertiger Metallersatz bietet Ihnen LPP beeindruckende Robustheit und gleichzeitig unübertroffene Anwendungseffizienz.

Welchen Nutzen Ihnen Tank Protection Shield® (TPS) bringt

Ergänzt wird LPP durch Tank Protection Shield® (TPS), ein dauerhaftes Versiegelungsharz auf Epoxy-Vinylester-Basis. Diese Kombination verspricht eine langanhaltende Abdichtung sowie umfassenden Korrosionsschutz. Mit TPS erhalten Sie Sicherheit und Effizienz – ohne die Risiken, die Schweißarbeiten mit sich bringen können.

Kosten senken und Werte erhalten

Mit LPP und TPS setzen Sie auf eine bewährte, effiziente und sichere Methode, um Korrosion und Leckagen effektiv zu bekämpfen. Profitieren Sie von langanhaltendem Schutz und sichern Sie die Werterhaltung Ihrer Anlagen.

Lernen Sie hier auch die Tank Protection Shield Service GmbH & Co. KG kennen, die die Sanierungsarbeiten bei Ihnen vor Ort sicher, zuverlässig und effizient ausführt.

-

7. Behörden- und Richtlinien- konform33 11

-

6. Aufkantung umläufig 10 cm79 67

-

1. Abrasiv gereinigter Untergrund24 82

-

2. Dauerbeständiges Versieglungsharz auf Epoxy-Vinylester Basis32 82

-

3. Carbonfaservlies45 82

-

4. Dauerbeständiges Versieglungsharz auf Epoxy-Vinylester Basis58 82

-

5. Flüssigkeitsdichte Auskleidung DIBt zugelassen, 2000 Mikrometer71 82

Behörden-

und Richtlinien-

konform.

Detaillierter Abschlussbericht inkl. Betriebsanweisung

So wie unsere Erfassungsberichte, entsprechen auch unsere Abschlussdokumentationen, nach erfolgter Sanierung, den Anforderungen der AwSV und des WHG.

Der Kunde bekommt eine ausführliche, leicht verständliche Dokumentation ausgehändigt, die eine Betriebsanweisung enthält und das weitere Vorgehen im Schadensfall beschreibt und sicherstellt.

Die behördlichen Vorgaben sind erfüllt und der Prozess für den Kunden nachvollziehbar.

Sanierung in mehreren

Arbeitsgängen

Häufig gestellte

Fragen zur

Domschacht-

sanierung

Hier finden Sie Antworten auf die häufigsten Fragen. Wir haben die wesentlichen Informationen für Sie zusammengestellt, um Ihnen rasch weiterzuhelfen. Sollten Sie weitere Fragen haben, sind wir jederzeit gerne für Sie da.

Wie lange dauert eine Domschachtsanierung?

Die Sanierung eines Domschachts nimmt in der Regel zwischen 2 und 3 Tage in Anspruch. Unsere Experten arbeiten effizient und gewissenhaft, um sicherzustellen, dass Ihre Anlage schnell wieder voll funktionsfähig ist.

Was kostet eine Domschachtsanierung?

Die Kosten für eine Domschachtsanierung variieren je nach spezifischen Anforderungen, Größe und Zustand des Domschachts. In der Regel bewegen sich die Preise zwischen 3.850 und 4.500 Euro. Wir bieten eine transparente Kostenaufstellung, um Ihnen eine präzise Planung zu ermöglichen.

Kann mein Betrieb während der Sanierungsarbeiten normal weiterlaufen?

Ja, die Durchführung der Domschachtsanierung beeinträchtigt Ihren laufenden Betrieb nicht. Unser Ziel ist es, die Beeinträchtigungen für Ihre täglichen Abläufe und Ihr Geschäft so gering wie möglich zu halten.

Bietet KH Tank- und Korrosionsschutz auch Dienstleistungen in Österreich und der Schweiz an?

Ja, wir sind für unsere Kunden in der gesamten D-A-CH Region tätig. Ob Ihr Standort in Deutschland, Österreich oder der Schweiz liegt – wir stehen Ihnen mit unserem Fachwissen und unseren Leistungen zur Verfügung.

Ich habe ein Loch im Domschacht – können Sie helfen?

Definitiv, ja. Mit unserer innovativen Lösung, dem Liquid Power Plate, können wir Leckagen schnell, effektiv und dauerhaft abdichten. Verlassen Sie sich auf uns für eine zuverlässige Instandsetzung.

Muss ich vor Ihren Sanierungsarbeiten etwas vorbereiten?

Sie brauchen sich um nichts zu kümmern. Unser Team übernimmt die gesamte Vor- und Nachbereitung. Ihre Zufriedenheit und der Schutz Ihrer Anlage stehen bei uns an erster Stelle. Wir empfehlen dennoch die Sonden auszubauen, da die sehr empfindlich sind.

Wie lange beträgt die Gewährleistung von KH Tank- und Korrosionsschutz für die Domschachtsanierung?

Wenn Sie sich für unseren Wartungsvertrag entscheiden, bieten wir eine Gewährleistung von 5 Jahren auf die durchgeführten Sanierungsarbeiten. Dies garantiert Ihnen langfristige Sicherheit und Zuverlässigkeit Ihrer Anlage.

Wann wird nach dem Auftrag mit der Ausführung der Sanierungsarbeiten begonnen?

Nach Auftragserteilung planen wir den Beginn der Sanierungsarbeiten in der Regel für etwa 8 Wochen später ein. Dies er möglichst eine sorgfältige Vorbereitung und Planung, um die Arbeiten effizient und zu Ihrer vollsten Zufriedenheit durchzuführen.

Welche Unterlagen benötigen Sie für ein Angebot?

Für die Erstellung eines detaillierten Angebots benötigen wir idealerweise den Prüfbericht vom Sachverständigen sowie Fotos der zu sanierenden Domschächte. Diese Informationen helfen uns, den Umfang der notwendigen Arbeiten genau zu bestimmen.

Entspricht die Domschachtsanierung durch KH Tank- und Korrosionsschutz allen gesetzlichen Anforderungen?

Ja, unsere Sanierungsarbeiten erfüllen sämtliche gesetzliche Anforderungen. Sie können sich darauf verlassen, dass Ihre Anlage nach der Sanierung den aktuellen Standards und Vorschriften entspricht.

Was sind die Risiken, wenn der Domschacht nicht saniert wird?

Wird ein Domschacht nicht fachgerecht instandgehalten, können verschiedene Probleme auftreten. Undichtigkeiten können sich entwickeln, Schrauben am Tankdomdeckel können korrodieren und den Deckel unzugänglich machen. Außerdem besteht die Gefahr, dass Wasser in die Armaturen eindringt und einen Ausfall der gesamten Tankanlage verursacht. Die regelmäßige Wartung und rechtzeitige Sanierung sind daher essenziell, um kostspielige Reparaturen und Betriebsausfälle zu vermeiden.

Ich habe einen Mängelbericht erhalten. Können Sie mir helfen?

Selbstverständlich stehen wir Ihnen zur Seite, wenn bei einer Sachverständigenprüfung Mängel an Ihrem Domschacht festgestellt wurden. Bitte übermitteln Sie uns den Mängelbericht. Unser Team wird sich umgehend um die Behebung kümmern, damit Ihr Domschacht schnellstmöglich wieder den Vorschriften entspricht.

Wie funktioniert eine Domschachtsanierung?

Um Ihnen einen detaillierten Einblick in den Ablauf einer Domschachtsanierung zu geben, haben wir auf unserer Webseite ein informatives Erklärvideo bereitgestellt. Dieses Video zeigt Ihnen Schritt für Schritt den gesamten Prozess und vermittelt Ihnen ein klares Verständnis der notwendigen Arbeiten.

Wie hoch sind die Anfahrtskosten?

Die Anfahrtskosten für unsere Serviceleistungen variieren je nach Ihrem Standort. Generell unterscheiden wir zwischen Anfahrten innerhalb von Nordrhein-Westfalen (NRW) und außerhalb dieses Gebiets. Um Ihnen eine genaue Auskunft geben zu können, kontaktieren Sie uns bitte mit Ihrem Standort, und wir informieren Sie über die anfallenden Kosten.